Introduction

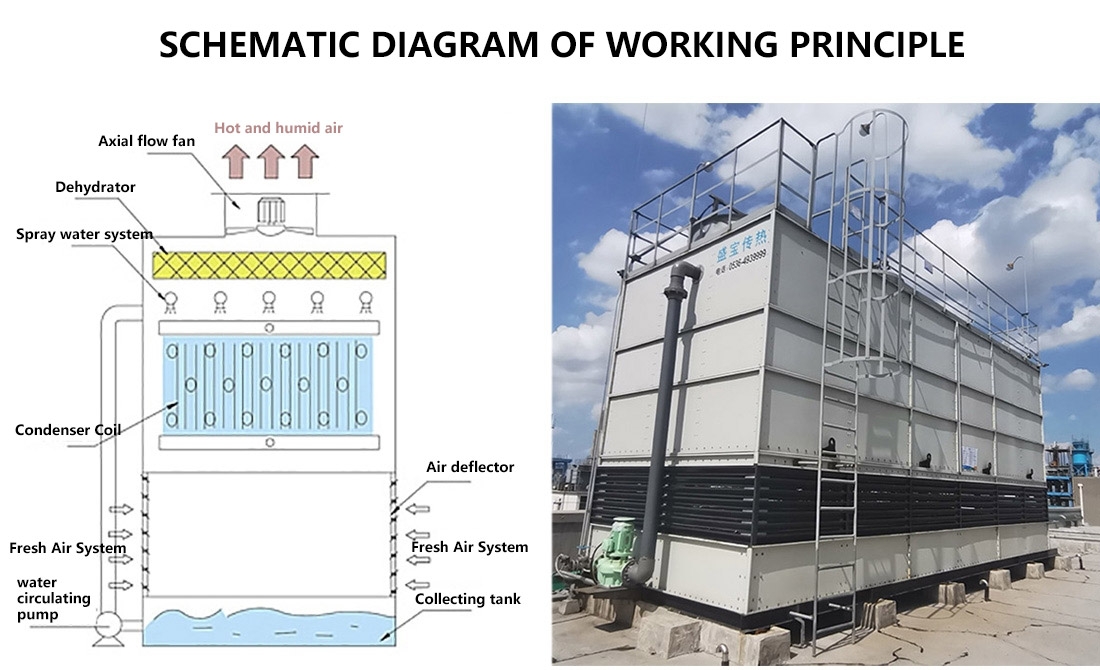

The Closed cooling tower is a type of closed cooler used in the manufacturing industry. Equipment that requires water for cooling is very common. Traditional water cooling methods consume a lot of water and have high maintenance costs for operation and use of equipment. The working fluid of the cooling tower is in a closed cycle, using high-efficiency heat exchange circular tubes as heat conductors, and heat is exchanged through air. The significant features of using a closed cooling tower are stable circulating water quality, high heat transfer efficiency, and low operating costs.

Strong corrosion resistance and rich experience

Strong corrosion resistance and rich experience Quality Installation Quality Assurance

Quality Installation Quality Assurance Stable operation and after-sales service

Stable operation and after-sales service The strength of manufacturers continues to improve

The strength of manufacturers continues to improve

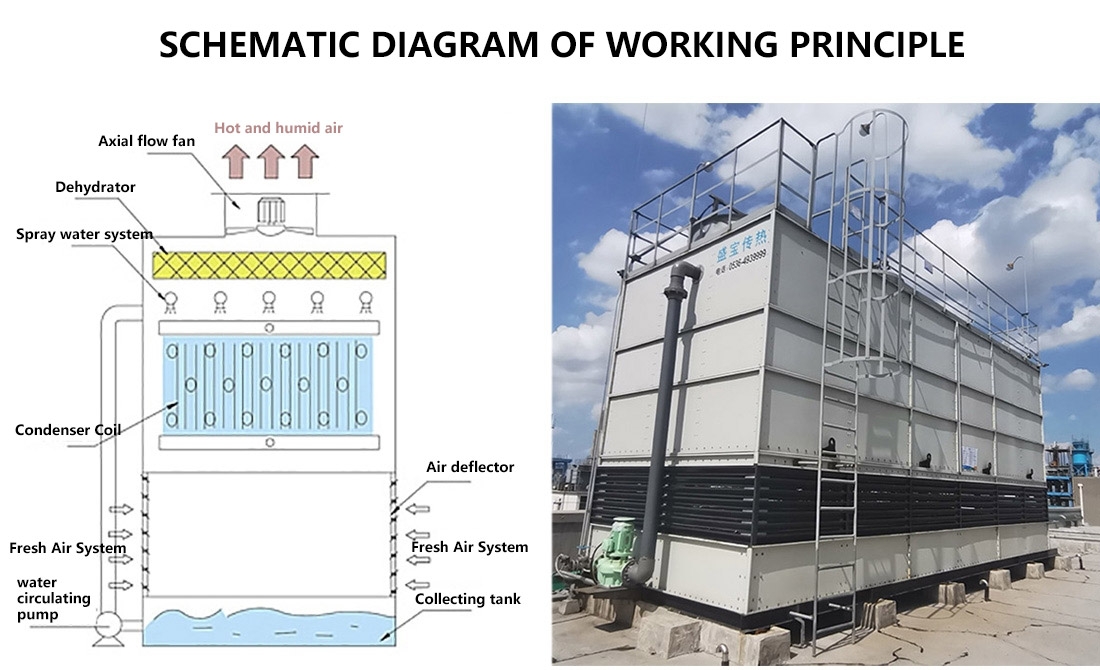

Working principle

◆Mainly relying on the rapid evaporation of the water film on the outer surface of the pipe to enhance the heat transfer outside the pipe, thereby achieving the purpose of cooling the soft water inside the pipe. This is mainly because water has a high latent heat of vaporization (the latent heat of vaporization of water at one atmosphere is 570 kal/kg), which greatly improves the overall heat transfer efficiency. When the equipment is running, the evaporation of the water film on the outer surface of the tube causes the humidity of the air to greatly increase and approach saturation after passing through the tube bundle. The axial flow fan extracts the humid air and passes it through the mist eliminator located above the water spray system, removing the water droplets carried in the humid air and discharging it into the atmosphere through the air inlet. Because the axial flow fan is located at the upper part of the equipment, a negative pressure area is formed at the lower part of the axial flow fan when air is drawn upwards, which accelerates the evaporation of the water film on the outer surface of the pipe and enhances the heat transfer outside the pipe.

Advantage

50% water-saving compared to open cooling towers

10% more energy-efficient than open cooling towers

Reduce emissions by 50%

Easy maintenance and low maintenance costs

Closed cycle, water quality is not polluted

Constant cooling water temperature

Significant water-saving and energy-saving effects

A wide range of applications

Anti clogging, anti-corrosion

Application

◆ Induction heating and metal melting equipment, such as high and medium frequency quenching equipment, medium frequency power supply and cooling for electric furnaces, induction furnaces, insulation furnaces, etc;

◆ Cooling of circulating water for various reactors and condensers in the chemical industry;

◆ Cooling of industrial solutions. Such as quenching solution, electroplating solution, etc;

◆ Cooling for large molds such as metal die-casting molds and injection molds. The most commonly used industries are air conditioning cooling, freezing, and plastic chemical industry;

◆ Cooling of large motors, diesel engines, rectification equipment, welding equipment, hydraulic stations, and continuous casting equipment, etc;

◆ Need for closed recycling of media that pollute the environment;

◆ Medium with large cooling amplitude;

Current Location:

Current Location:

Strong corrosion resistance and rich experience

Strong corrosion resistance and rich experience Quality Installation Quality Assurance

Quality Installation Quality Assurance Stable operation and after-sales service

Stable operation and after-sales service The strength of manufacturers continues to improve

The strength of manufacturers continues to improve

Closed cooling tower

Closed cooling tower Closed cooling tower

Closed cooling tower Dry wet combined closed cooling tower

Dry wet combined closed cooling tower Closed tower

Closed tower

Home

Home

Products

Products

Phone

Phone